-

- Products

- Indoor Household Cords

- Appliance Cords

- General Purpose Short-Length Cords

- General Purpose Extension Cords

- Landscape & Decorating Cords

- Bright Color Extension Cords

- Oil-Resistant Extension Cords

- Cold-Flex Extension Cords

- VividFlex Power Cords

- EXTREME All-Weather Cords

- Cord Management

- Task Lights

- Adapters & GFCI Devices

- Where to Buy

- About

- Careers

- Glossary

- Catalog

- Products

- Indoor Household Cords

- Appliance Cords

- General Purpose Short-Length Cords

- General Purpose Extension Cords

- Landscape & Decorating Cords

- Bright Color Extension Cords

- Oil-Resistant Extension Cords

- Cold-Flex Extension Cords

- VividFlex Power Cords

- EXTREME All-Weather Cords

- Cord Management

- Task Lights

- Adapters & GFCI Devices

- Where to Buy

- About

- Careers

- Glossary

- Blog

-

-

Enhancing Cable Integrity with Advanced Monitoring Technologies to Prevent Failures

In today's rapidly evolving technological landscape, ensuring cable integrity is paramount for the sustained performance of various industries, especially in telecommunications and energy sectors. According to the International Electrical Engineering Institute, cable failures can lead to costly downtimes, with estimates suggesting that ineffective cable management results in losses exceeding $4 billion annually worldwide. Advanced monitoring technologies have emerged as crucial tools in preemptively identifying potential failures, thus safeguarding assets and reducing financial impacts. By leveraging real-time data analytics and predictive maintenance strategies, organizations can enhance cable integrity, ensuring reliability in service delivery and optimizing operational efficiency. As the reliance on robust infrastructure increases, the integration of these technologies becomes not only beneficial but essential for future resilience.

Table of Contents

[Hide]

Leveraging IoT Sensors for Real-Time Cable Condition Monitoring

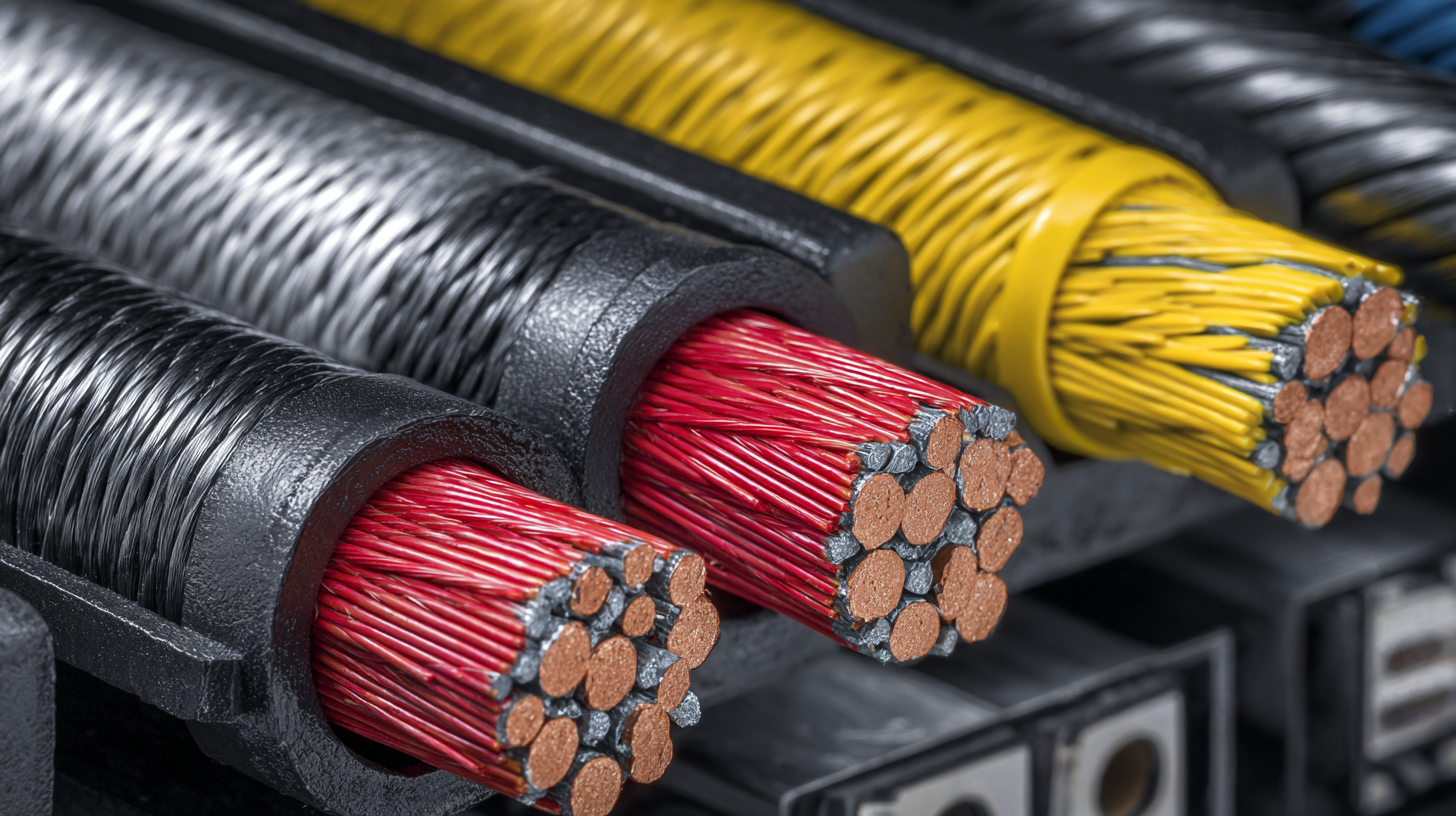

In an era where technology continuously evolves, leveraging IoT sensors for real-time cable condition monitoring is becoming crucial for maintaining cable integrity. These advanced monitoring technologies provide insights into the health of electrical and communication cables, enabling operators to identify issues before they escalate into failures. By continuously tracking parameters such as temperature, humidity, and mechanical strain, IoT sensors can send alerts and diagnostics that help maintain optimal performance.

**Tip:** Consider choosing IoT sensors with enhanced data analytics capabilities. This feature allows for better predictive maintenance, reducing not only downtime but also repair costs associated with sudden cable failures.

Integrating these monitoring solutions into existing infrastructure needs careful planning. Companies should assess their current systems and identify which areas could benefit most from IoT technology. As the data collected by these sensors can be vast, implementing a robust analytics platform will ensure that crucial insights are extracted effectively.

**Tip:** Regularly review your monitoring system's data and improve calibration procedures. Keeping your sensor data accurate ensures reliable monitoring, which is vital for preventing unexpected performance degradation in cables.

Enhancing Cable Integrity with Advanced Monitoring Technologies to Prevent Failures - Leveraging IoT Sensors for Real-Time Cable Condition Monitoring

| Cable Type | Monitoring Technology | Sensor Type | Condition Metrics | Status |

|---|---|---|---|---|

| Power Cable | Optical Fiber Monitoring | Temperature & Strain Sensors | Temperature, Strain, Voltage | Operational |

| Communication Cable | Wireless Monitoring | Environmental Sensors | Humidity, Temperature | Warning |

| Data Cable | IoT Edge Monitoring | Current Sensors | Current, Voltage | Critical |

| Industrial Cable | Centralized Monitoring | Vibration Sensors | Vibration, Temperature | Operational |

| Submarine Cable | Remote Monitoring | Pressure Sensors | Depth, Pressure | Warning |

Integrating AI Analytics to Predict Cable Failures Before They Happen

In today’s rapidly evolving technological landscape, the importance of cable integrity cannot be overstated. Advanced monitoring technologies, particularly the integration of AI analytics, play a crucial role in predicting cable failures before they occur. According to a recent report by Markets and Markets, the global market for predictive maintenance is projected to reach USD 23.4 billion by 2025, emphasizing the growing demand for proactive solutions in facilities management. Leveraging AI allows for real-time data analysis, enabling utilities and organizations to identify potential failure points in their cable infrastructure.

Utilizing AI-driven analytics, companies can predict failures with up to 95% accuracy, significantly reducing operational downtime and maintenance costs. Tips for implementing these technologies include ensuring adequate sensor deployment along critical cable routes and continuously training AI models with historical data to improve prediction reliability. This proactive approach not only enhances cable integrity but also aligns maintenance schedules with actual needs rather than relying on outdated models.

Organizations should also consider integrating machine learning algorithms that analyze not just cable conditions, but also environmental factors impacting performance. Consistent monitoring harnessed through AI can lead to a substantial reduction in the total cost of ownership for cable infrastructure, showcasing a true return on investment while ensuring safety and reliability.

Utilizing Drones and Robotics for Enhanced Inspection of Cables

The utilization of drones and robotics for enhanced inspection of cables is becoming increasingly crucial as industries strive to maintain cable integrity and prevent failures. Leveraging advanced monitoring technologies, drones equipped with AI-powered algorithms can perform aerial inspections that drastically reduce the time and effort involved in traditional inspection methods. For instance, the offshore drone inspection market is projected to grow significantly, from approximately $548 million in 2025 to nearly $1.86 billion by 2035, showcasing a compound annual growth rate (CAGR) of 13%. This growth is indicative of the rising demand for automated solutions in infrastructure maintenance.

Moreover, the integration of robotics in this sector not only facilitates real-time monitoring but also enhances safety by mitigating the risks associated with manual inspections. With the advent of advanced drones capable of autonomous operations, routine inspections can be conducted with greater accuracy, allowing for the early detection of anomalies. For example, AI-based image anomaly detection is revolutionizing industrial inspection contexts by streamlining quality assurance processes and improving reliability. This shift towards automation and robotics is imperative as industries face environmental challenges and the need for more efficient infrastructure maintenance solutions.

Implementing Data-Driven Maintenance Strategies to Extend Cable Lifespan

Implementing data-driven maintenance strategies is crucial for extending the lifespan of cables in various applications. By utilizing advanced monitoring technologies, companies can gather real-time data on cable performance, which helps identify wear and potential failure points before they escalate into costly outages. These strategies incorporate predictive analytics to assess the condition of cables, enabling maintenance teams to act proactively rather than reactively.

Tips: Regularly schedule data analysis sessions to review the performance metrics of your cables. Consider using machine learning algorithms that can process large datasets to detect patterns and anomalies that might indicate an impending failure.

Moreover, integrating Internet of Things (IoT) devices within cable networks allows for an unprecedented level of monitoring. These sensors can provide insights into the environmental conditions surrounding the cables, such as temperature and humidity, which play a significant role in their deterioration. By marrying this data with maintenance schedules, organizations can create tailored strategies for each cable, ensuring optimal performance and longevity.

Tips: Invest in training your maintenance staff on data interpretation to foster an environment of informed decision-making. Collaborating with technology partners can also enhance your capability to develop customized monitoring solutions that fit your specific operational needs.

Exploring Industry Standards and Regulations for Cable Monitoring Technologies

In the realm of cable monitoring technologies, industry standards and regulations play a pivotal role in ensuring the reliability and safety of power and communication networks. The International Electrotechnical Commission (IEC) has established guidelines that emphasize the importance of regular monitoring to detect potential failures before they occur. According to a report by the Global Industry Analysts, the market for cable monitoring systems is projected to reach approximately $6.2 billion by 2026, driven largely by rising safety demands and the need for preventive maintenance.

Furthermore, the adoption of standards such as IEEE 1525, which focuses on the monitoring and management of cable infrastructures, is critical for enhancing operational reliability. This standard outlines best practices for installing and utilizing monitoring technologies, ensuring compliance with both national and international safety protocols. A significant study by the Network Reliability and Quality Assurance (NRQA) found that utilities employing advanced monitoring technologies reported a 30% reduction in cable failures, showcasing not only the effectiveness of adherence to standards but also the potential cost savings for organizations that prioritize preventive measures.